Infrastructure Asset Management

| |

Three Elements to Developing your Asset Management Program

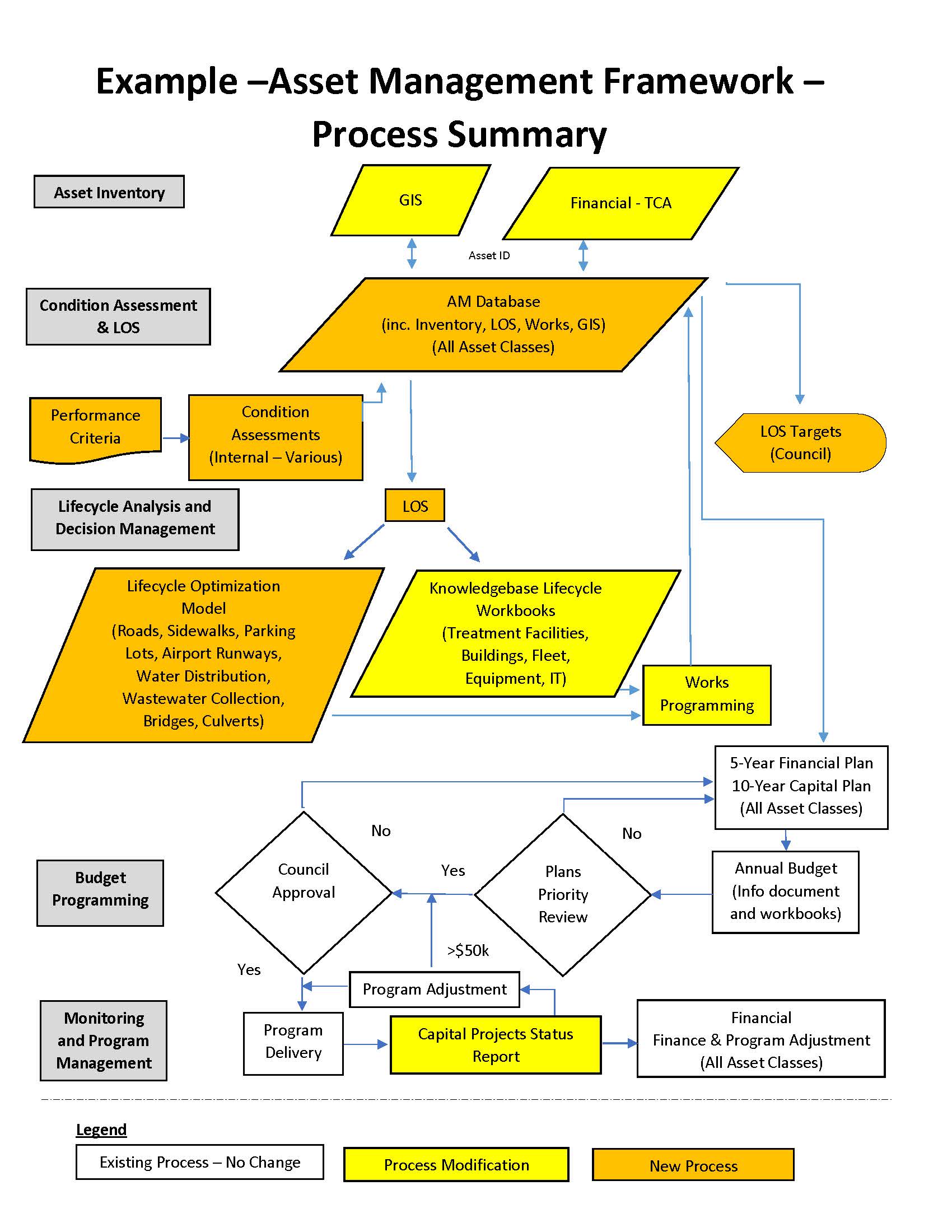

- Develop the Strategic Framework - Charting the organizational and process flow

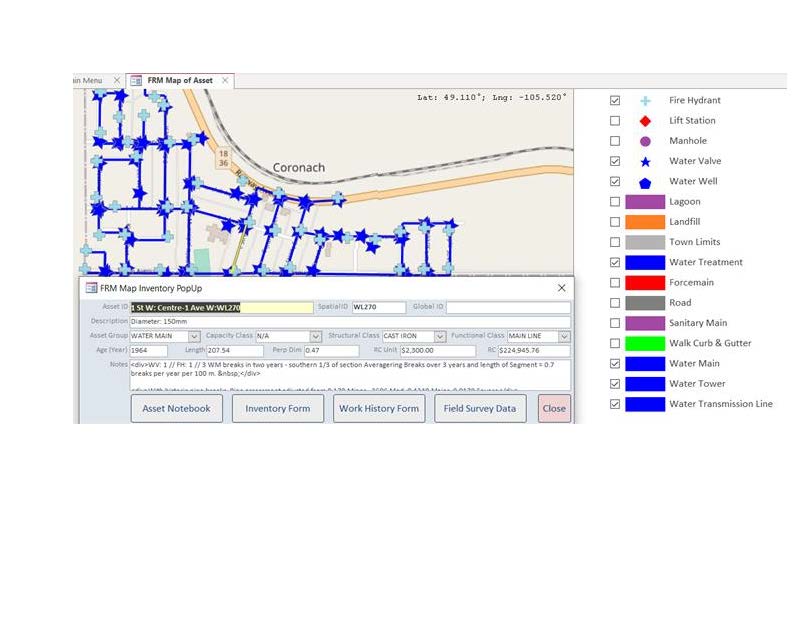

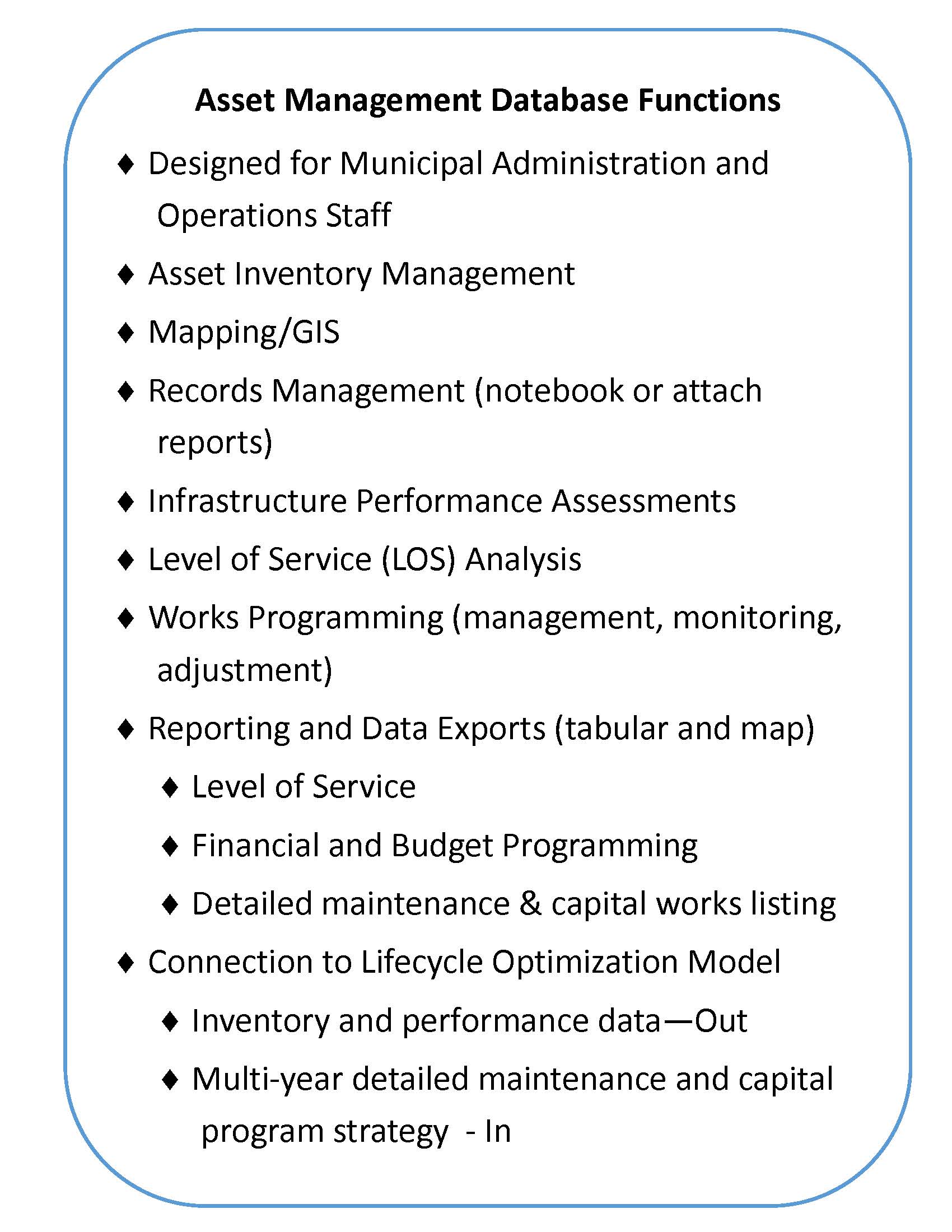

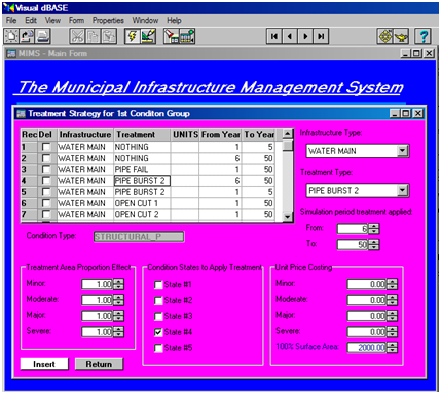

- Implement the Asset Management Program - Pulling together processes, systems, data, and analysis

- Sustain and Manage the Asset Management Program - Ongoing administration and operations

| |