Asset Management Innovation Examples

Pillar Systems’ team leader is a two-time recipient of the “Alberta Minister’s Award of Excellence for Innovation”. We are recognized and award winning in other areas. Innovation and best practice have become part of the Pillar Systems corporate culture. The following are a few examples that evolved out of our applied practice in the research & scientific community and industry.

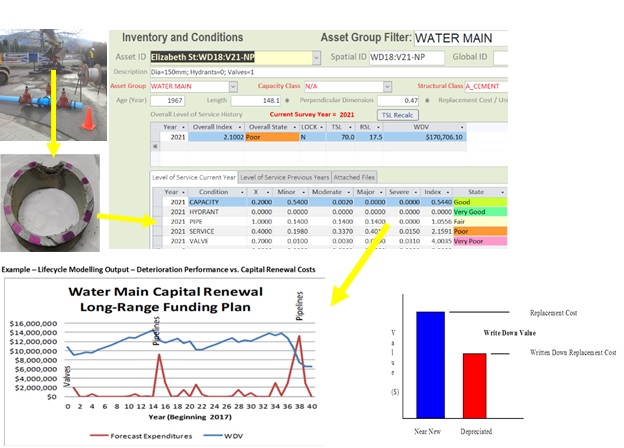

Water Main (Cast Iron and Asbestos Cement) Pipe Testing and Analysis

The most difficult asset classes to attain reliable and cost-effective condition data are those that are buried and inaccessible. Smaller pressure pipes (e.g. water mains) are much more difficult than the larger gravity pipes (e.g. sanitary & stormwater mains).

We have applied a continuous pipe testing apparatus inserted through one fire hydrant and received at another hydrant. While this serves great benefit in delivering continuous measurement through the pipe, it is costly and often unreliable in getting a reading due to the measuring device getting hung up.

We addressed this through a collaborative working approach with municipal operations staff. During maintenance operations, including a pipe break or valve replacement, we would extract a pipe sample. We would test the sample to provide a current day condition state and apply Markovian probabilistic modeling to assess the remaining service life (RSL). Over time, a library is created listing the condition assessments, pipe material, and age. This is used to correlate a condition assessment for the remainder of the piping network for use in lifecycle optimization modeling.

The benefit is that a “waste material” becomes a valuable (and cost efficient) source of information impacting the decision-making of millions of dollars in capital renewal budget programming.

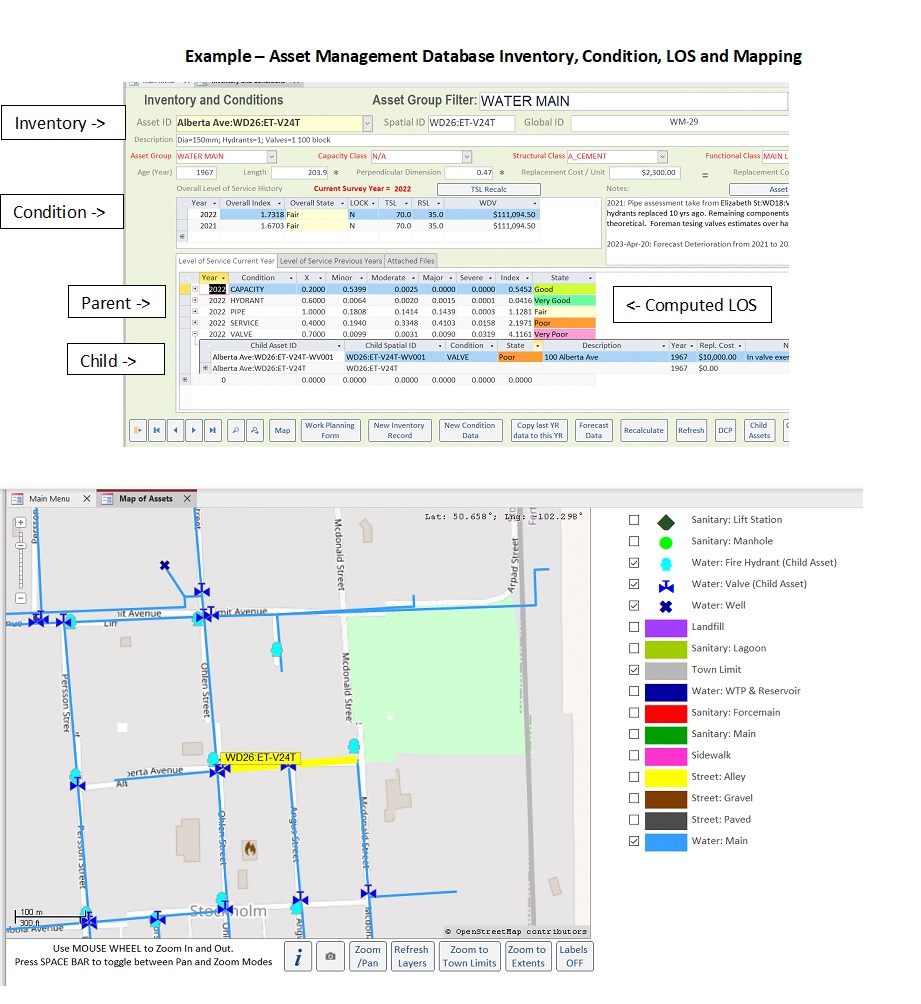

Parent Asset to Child Asset Relationships

In lifecycle analysis the interaction of the parent asset (e.g. water main) to its child asset (e.g. valves, hydrants, and service connections) is very important in decision management.

We addressed this in two ways. First, we developed our “Performance Criteria” to consider the child assets as a condition type to the parent asset. Then we created the Parent-Child relationship in our Asset Management Database, including a GIS link carrying through this relationship. This provides the opportunity to manage the unique characteristics of each child asset and relate an overall condition assessment to the parent asset.

Effective Lifecycle Optimization Modeling – Preservation Maintenance

A fundamental element of asset management is integrating a wide variety of lower cost preservation maintenance within the capital renewal program delivered at the right time. This is paramount to delivering a sustainable asset management program that provides a higher level of service and lower annualized cost over the lifecycle.

The issue is that in many lifecycle optimization technologies, including many pavement management systems, preservation maintenance treatments are not reliably modelled. Often, they only deliver replacement at the end of the lifecycle. This is due to modeling with the compiled condition states that can’t address treatment impacts to only part of the asset.

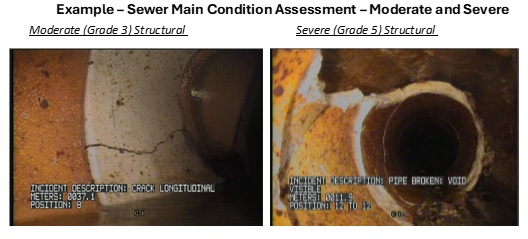

We addressed this by carrying through the raw severity (%minor, %moderate, %major, %sever) – extent (%) data through the lifecycle analysis instead of the compiled condition states (very good, good, fair, poor, very poor). This provides the detail that mitigated the inherent modeling error. As such this results in reliable lifecycle optimization modeling and inclusion of preservation maintenance treatments blended into the overall treatment strategy.

In the following sewer main example, a pipe with any amount of moderate severity cracking is not an immediate risk. However, if not addressed the pipe will continue to deteriorate to the point of failure. Our model accounts for the extent (%) of moderate severity cracking and presents treatment options of “Nothing”, “Spot Line”, “Continuous Line”, or "Replace". This provides the detail to consider a host of spot repair treatments early (i.e. at the right time) in the lifecycle. This is proven to "address issues before they become problems" and enhance delivery of a reliable infrastructure program the community.

Unique components of our modeling technology includes:

- Generic to any infrastructure type

- Detailed life-cycle analysis open to any maintenance and capital treatments

- Ability to consider risk of consequence and variability in level of service as required between infrastructure classes (eg. main lines vs. branch lines)

- Monetary performance measure, which provides a dollar to dollar comparison between input expenditures to output asset valuation